Overview Of Plastic Injection Mold

In day-to-day business, automakers do realize the importance of plastic parts in the process of designing the complete vehicle. The plastic is molded into diverse shapes for making the automobile parts due to its lighter weight and has the facility to save much energy. Plastic injection molding is the method of manufacturing parts made of thermoplastic by melting and forcing into molds where they cool to form the desired object

How does plastic injection molding work?

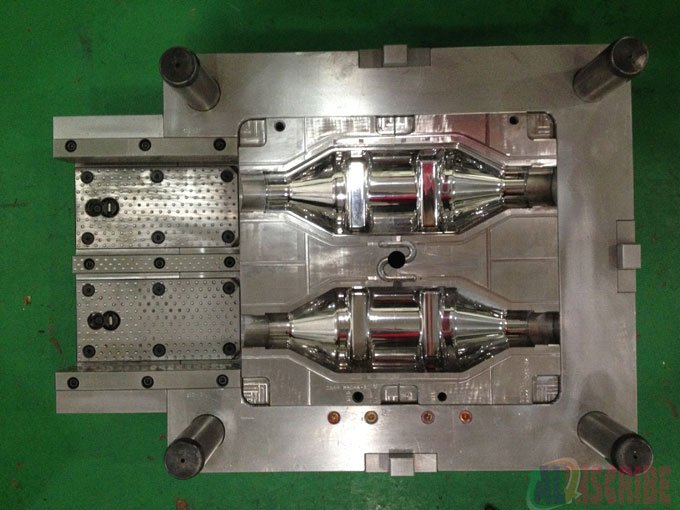

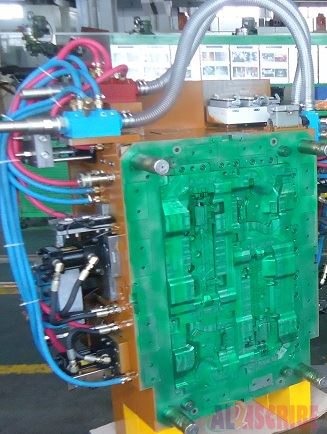

The process of plastic moulding usually begins with an industrial engineer who designs a product. This is followed up by the work of a toolmaker or mold maker who makes the mold to fit the design created. These molds are metallic and usually made using steel as well as aluminum. Using machines, they are made to acquire the exact shape desired by the design. Once this is done, the process of actually making the plastic follows. This involves thermoplastic being fed into the heated barrel and mixed. This melted material is then forced into the cavity of a mold and there it has to cool then harden to form the desired part.

Some characteristics of the process of plastic molding .

1. It uses melted and mixed thermoplastic or thermoset plastic as the base

2. It uses a plunger which acts like a screw or a ram to force the melted material into the mold

3. It makes a shape that is open-ended and has taken the shape of the cavity of the mold

4. It shows a parting line and gate marks on the finished products and the ejector pin marks can also usually be made out.

The contribution of plastic molding to Automobile industry

The contribution of plastic molding manufacturing to the automobile industry everywhere there is a huge demand for plastic in the automobile industry, mainly because of its lighter weight, making way for the successful production of automobiles.The plastic automated molding parts are quite popular in the automobile industry only because of the easy accessibility for designs and shapes.

It is through this injection molding tool that the basic vehicle parts are made for the smooth running of the vehicle. There are a large number of mold makers emerging, who are well skilled to perform this job as the market has now widely introduced advanced techniques and procedures. So, what are the applications of Automotive Parts Molding as in the industrial practices are considered? Flexibility and easy accessibility would be the preferred reasons and applications range from creating fresh accessories to spare auto parts.

Various plastic parts from various techniques and makers in the industry Plastic molding factory have the capacity to manufacture various products ranging from deeper interior parts, bumpers, door trims, spare parts, breaking system to spoilers in huge quantities, in various designs and shapes too. Only with the right type of molding right kind of automobile product part and design can be obtained. All the automobiles while designing undergo a huge molding process for accurate functionality.

There is an expert professional team of engineers and designers present who put in a lot of effort through the machines during the mold making process. This excellent contribution brings in high-class quality automobile equipment and finished products. However; it is absolutely in the hands of a mold maker as in the way he deals with the plastic material according to the best industry standards. People keen to know the internal structure design part and product integration can visit our website for the more detailed exposure on automobile spare parts molding process.

Article Comments

Similar Articles

Articles Search

Sponsor

There are zero sub-categories in this parent category.

There are zero sub-categories in this parent category.

There are zero sub-categories in this parent category.