Importance Of ERP Software For Oil And Gas Industry

Like many in the Energy and Resources Industry, the oil and gas industry encompasses a strong focus on the Environment, Health, and Safety (EHS) as a means of driving operational excellence and ensuring that employees find a safe place to work. It plays an influential role in the global economy as the world’s essential oil fuel sources. The processes involved in the production and distribution of oil and gas are extremely complex, capital intensive, and basically require state-of-the-art technology. This industry is often divided into three categories:

- Upstream, the business of exploration and production of oil and gas

- Midstream, storage and transportation

- Downstream, includes refining and marketing

An Oil and Gas Industry faces challenges in ensuring safety protocols are followed consistently during everyday business operations as the traditional paperwork like safety checklists and inspections are hard as they are difficult to read at times and costly too. Not only this but there are other issues as well which thwart output like communication gap between their drilling engineers in the field or offshore and the supervisor.

ERP (Enterprise Resource Planning) software helps automates business systems and provides insights and internal control. It utilizes a central database to collect data from multiple departments such as manufacturing, allocation and budgeting, sales and marketing, human resources, and distribution network. ERP Software for Oil and Gas Industry includes modules bearing obligations to lessen difficult work and time as much as possible. Appropriate dashboard with an admin panel will help managers and owners to fetch details, handle operations, and project resources and inventory whenever they need. ERP integration is being pursued by a mounting number of oil and gas partnerships in order to automate business activities and hence, optimize their document management process.

Why implementing ERP software for Oil and Gas Industry is crucial?

The oil and gas industry is considered as one of the most important industries that generated approximately $2.1 trillion in 2021. To standardize all the departments can be a hustle for a big organization. Therefore, the implementation of ERP software for Oil and Gas Industry is adopted by companies all around the globe. Studies have depicted that ERP is an effective software platform for oil and gas businesses to boost their efficiency. However, it totally depends on the company and how they utilize the system within its walls. Standardizing corporate operations in the oil and gas industry is necessary because of the oil and gas industry’s massive units and divisions, which are geographically dispersed, and complex supply chain needs, and increased competition.

Must read the article Role of ERP in Logistics and Supply Chain Management

The main aim of standardization is not only about cost savings, but also concerns about the viable value and flexibility offered to the firm by allowing swift mobility into the international market and adaptations of workload in offices. Uniformity is critical for any business with several units distributed geographically, a huge number of wells, byzantine and intricate supply chain, and intensifying rivalry. The primary objective of implementing ERP software for Oil and Gas Industry is to reengineer company processes via standardized enterprise applications and that’s why ERP is winning traction in the country Oman, with implementations occurring rapidly in a variety of industries, most remarkably manufacturing.

Read the article Top 10 ERP Software for Manufacturing Industries

It’s a known fact that the oil and gas industry is a pricey and high-end sector. Companies must act sagaciously if they want to deploy ERP software for Oil and Gas Industry, otherwise, due to the lack of adequate information and updated knowledge, companies just might postpone the replacement of underperforming assets or prematurely update fully working assets and equipment. The companies must go through these steps if they wish to set up an ERP system:

- Pre-implementation Stage: The first step helps businesses determine why they want to implement ERP systems, what objectives they aspire to achieve with these systems, what preparations need to be done by corporations, and what key success factors they may require to facilitate successful implementation.

- Implementation Stage: Conventionally, organizational and technological challenges arise during implementation. This stage demands businesses to anticipate and prepare for future obstacles and problems that may emerge during this particular stage.

- Post-implementation Stage: Although this is the ultimate stage after implementation the work is not yet done. Companies must stay accustomed to new and innovative technologies to cope with market demands. As a result, they will be able to foresee a project’s success or failure.

Oil and Gas companies operate in a volatile and dynamic ecosystem, and they are having a propensity to fluctuations in foreign exchange rates and changes in regulatory compliances. Organizations related to petrochemicals and natural gas like Saudi Aramco, ExxonMobil, Total, etc. ride on unpredictable erratic waves of demand and supply and only ERP software for Oil and Gas Industry can offer them a holistic approach to all the operations and real-time data on resource availability.

Features to look for in ERP Software for Oil and Gas Industry:

1. Local and Global Financial Reporting:

This industry is quite global, as there are customers spread across the planet. We find wells in one country and refineries in another. Every country has its own tax system and structure built on sales revenue or quantity relocated to or from the locale. Conducting any kind of business implies that we must provide financial reports and analyses to the tax and regulatory authorities. ERP software for oil and gas industry helps to manage local reporting and balance the overall global burden.

2. Asset Management:

The assets which are required in this specific industry are not only expensive but convoluted as well. Whether it is an offshore drilling rig, a refinery, or a trans-national pipeline, billions of dollars are invested in them. ERP software for Oil and Gas Industry helps to keep those assets up and running, produce value consistently, and decide where they should be put to use for optimum exploitation. Depreciation and amortization are important components of financial reporting and ERP help to precisely calculate the lifetime of assets.

3. Oil Monitoring Solutions:

Blunders in protecting oil tankers or wells against combustible materials may precede major disasters in the adjoining areas. Monitoring oil tank level, temperature, distant oil wells/tanks, and water pressure can be done effortlessly with the ERP system’s Oil Well/Tanker Monitoring Solution. Furthermore, an IoT-powered ERP system will provide real-time data and assist in the implementation of preventive actions.

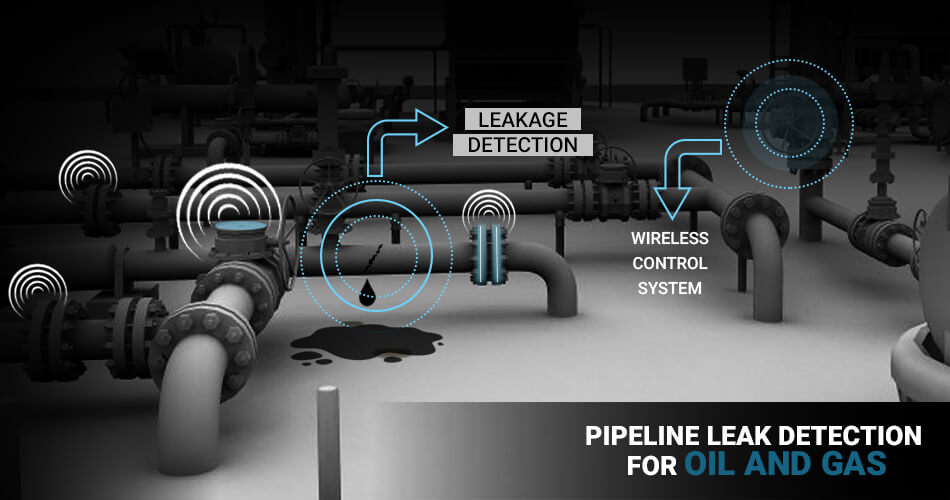

4. Pipeline Management:

Oil and Gas Industry is associated with complex gas pipeline structures. Monitoring the temperature of a gas pipeline tunnel is indispensable for safety. The temperature rises quickly in the confined interior of a tunnel and its overheating can cause pipeline cracks leading to gas leaks and even explosions. In order to get around, there is a feature called Remote Pipeline Temperature Monitoring System that involves multiple temperature sensors, gas sensors, and pressure sensors to invigilate temperature levels, leakage of gas and pressure at various points along the gas pipeline.

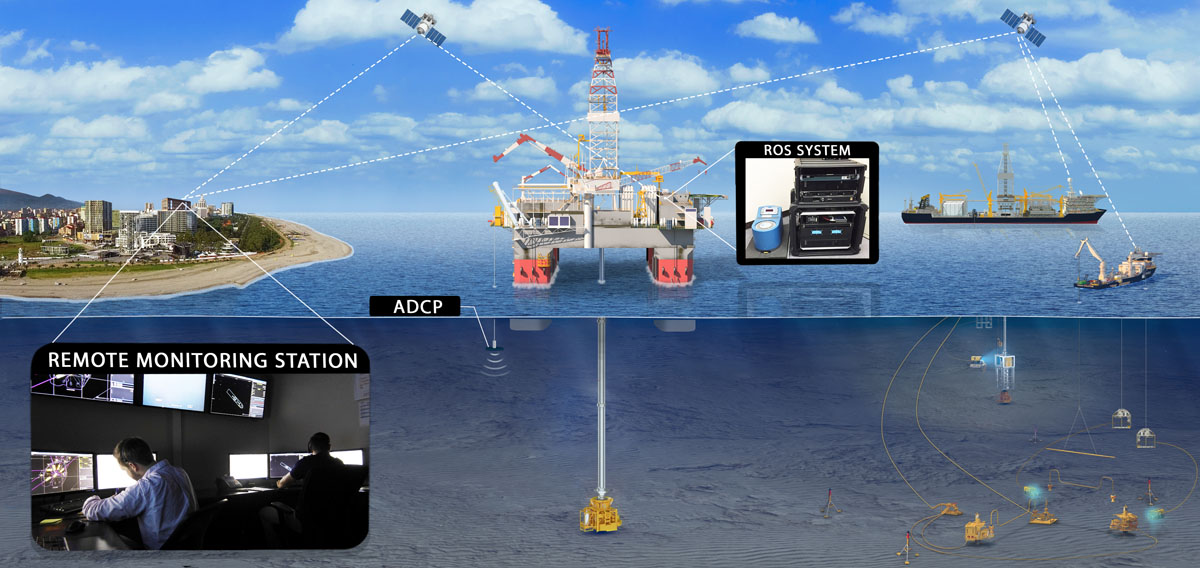

5. Offshore Rig Monitoring:

Since most of the equipment is below sea level, it becomes difficult to monitor pipelines offshore in the oil and gas sector. Various equipment such as interconnectors and machinery near the beginning site must be inspected on a routine basis. ERP system helps in monitoring the faults as well as the instrumentation of every foot of the pipeline.

6. Capacity Planning:

Capacity Planning for the oil and gas industry is no less than a hectic job. It is a complicated process that requires hit and trial method to achieve a reasonable forecast. Thus, ERP systems are specifically curated to focus on better automation, support for such processes, and more sophisticated analysis of historical data.

7. Data Cyber Security:

The oil and gas industry is now no stranger to cybersecurity attacks. It is discovered that oil and gas industry has experienced disruptions in supply due to cyberattacks where on average the disruption persisted for six days. An ERP software for oil and gas industry must have a strong security system that uses the latest encryption technologies.

List of ERP software for Oil and Gas Industry :

- DoFort

- Contata Solutions

- FortySeven Software Professionals

- GE Digital

- Enertia

- Epicor Kinetic

- Sage 300

- Infor

- IFS

- SAP

- Oracle NetSuite

- Deacom

Five Biggest Challenges Oil and Gas Industry is Facing:

1. The everlasting impact of Covid-19 on Oil and gas Industry:

Covid-19 has affected almost every industry and Oil and gas is one of them. As the industry started adapting social distancing and procedures that kept their workforce safe, there was a reduction in the headcount due to redundancies and an attempt to limit the number of employees working together. The operations resumed again but not with the same pace and definitely not without some practical challenges. Returning back to normal operations required significant investment in PPE equipment.

Besides, countries are endeavoring to reestablish their economies which may change the license to operate for oil and gas in some countries. For example government with reduced revenues from crude oil and petroleum exports due to crash in demand could lead to alterations in tax and regulatory frameworks governing oil producing nations.

Covid-19 proved that even a blatant issue with low-probability risks can bear significant loss potential and the industry’s vulnerability can spark wider discussions on global issues such as climate change. Despite being two years the world is still recovering and finding its way back to normalcy with a few uncertainties still lingering.

2. The Social Responsibilities:

The rise of the pandemic has showed green flags to prominent social issues like decarbonisation and greener environment agenda. We can evidence the rise of the social activist investors who are initiating more honest and open communication from organizations about their strategies and take on tackling global issues such as effects of climate change. According to the recent survey conducted by an international law firm, CMS, 37% of respondents across Europe, the Middle East, Latin America, Asia Pacific and Africa believed that climate change activism was the major issue of concern and represented a serious threat to the industry.

3. The Asset Protection of Oil and Gas Industry:

Protecting the assets has always been one of the biggest challenges the industry faces especially the increased concentration of exploration projects in areas prone to conflict of interest and unrest. The oil and gas infrastructure has been the key targets for piracy and terrorism. Back in 2016, the terror attacks aiming pipelines across Nigeria caused oil production levels dropped by 36% as per the reports.

4. Employees Safety:

This particular industry is quite vulnerable to kidnapping and ransom activities particularly in countries where instability and turbulence is common. They are targeted as the industry is perceived to be wealthy within the premises they operate. Perpetrators are well aware of the value of the assets they attack. There are multiple motivators behind kidnapping which go way beyond money, in few cases it can be for publicity or to convey political message.

The Middle East can depict more dangerous scenario where you have a significant terror community “Al Qaeda”, involved in kidnapping, extortion and killing for a much larger sum of money to fund their requirements. There must be solid understanding of the historic events of that area, groups that operate the sentiments of the local community, which will help to build perception of the potential risks.

5. Impacts of Climate Change:

Climate Change and Global Warming dominates the top-five global risks over the next decade, according to the World Economic Forum’s Global Risks Report. Reduction in pollution and emissions amidst lockdown has increased awareness of the environmental crisis around the globe.

The Oil and Gas Industry is seen as the biggest contributor of greenhouse gases universally, and that’s why organizations are being urged to come up with ideas which are more ethical and sustainable.

The need of the hour is robust and intelligent ERP software for Oil and Gas Industry to effectively manage the plethora of risks and threats as well ensure the safety of the people in and outside of the premises.

Conclusion

From the above discussion it is clear that implementing ERP software for oil and gas industry will only bring benefits for the companies that are managing their business in that niche. However, it also needs to be stated that, prior to the implementation, proper training should be given to the industry workers. As ERP systems can be quite confusing to work with, a training session will prove to be fruitful. This training session will not only help the workers but also make them aware of the potential benefits to be associated with ERP software for oil and gas industry.

Article Comments

Similar Articles

Articles Search

Sponsor

There are zero sub-categories in this parent category.

There are zero sub-categories in this parent category.

There are zero sub-categories in this parent category.