IoT ERP Integration: A Roadmap To Smart Business!

The ubiquitous term “Digital Transformation” highlights the need for analyzing the concept of IoT (Internet of Things) in the industry. ERP system is recognized as valuable software that has the ability to improve, upgrade and merge itself with different technologies and because of this attribute, it has been able to secure a higher position on the global market’s leaderboard. Two technologies that are important as ERP future trends are the IoT and Cloud Computing Technologies. The birth of Cloud ERP has unearthed new possibilities to operate IoT devices and utilize the technology to its fullest. IoT- one of the Digital Transformation technologies that require an internet connection, therefore, cloud services have become mandatory to use the full potential of Business Intelligence and Business Analytics. Digital Transformation offers various innovative ways and new technologies that have opened opportunities and given the company advantage in the global market. ERP vendors have now recognized the true potential of IoT technology and IoT ERP integration that they have embarked on their journey of developing their products with integrated IoT support.

Introduction to Internet of Things (IoT):

The internet is acknowledged by many as the biggest disruption of all time. It has enabled completely new forms of social interactions, activities, and organizations. It seems as if the next major technological revolution around the corner is IoT. As per the McKinsey report “Disruptive Technologies”: IoT is one of the top three technological advancements of the next decade, together with mobile internet and automation of knowledge work. Further, it states that “ The Internet of Things (IoT) is such a sweeping concept that it is a challenge to even imagine all the possible ways in which it shall affect business, economy, and society.”

The Internet of Things (IoT) refers to physical objects or group of such objects with sensors, processing ability, software, and technologies that connect with other devices and systems and exchange data over the internet or other communication networks. The companies have realized that IoT is capable of offering various improvements- smarter analytics, enhanced security (e.g. Cameras, smart doorbells), smart inventory, increased productivity, safer travel, and real-time demand visibility. One of the first ERP vendors offering IoT ERP integration are SAP and Microsoft. SAP offers a new methodology SAP Activate and the possibility to use IoT with their product called SAP s/4 HANA. On the contrary, Microsoft offers its product “Business Central”, which encourages working with Cloud Computing and IoT technology. Even large Chinese organizations are interested in integrating IoT in their day-to-day lives and so they have started exploring the potential of smart devices.

Latest Findings: IoT Statistics

- It is professed that the number of active IoT devices will surpass 25.4 billion around 2030.

- By 2025, there will be approximately more than 152,200 IoT devices connecting to the internet per minute.

- IoT-integrated solutions have the potential to generate $5-11 trillion in economic value by the year 2025.

- The consumer market with respect to IoT is estimated to reach $142 billion by 2026 at a CAGR of 17%.

- The quantity of data produced by IoT devices is anticipated to reach 73.1 ZB by 2025.

Even these statistics, research, and discussions give a clear sign that interest in digital transformation is present.

Benefits of IoT ERP Integration:

Businesses today, are evolving rapidly and becoming more engaged and interactive with their customers. Initially, ERP applications were never meant to receive external data from sensors but with the gradual shift in organizations to become more “digital”, there is a need to adopt data from IoT devices. IoT has now collaborated with ERP solutions and has led to some amazing benefits not only for organizations but for users as well.

Major benefits of integrating ERP with IoT technology:

1. Enhanced Data Quality:

By enabling IoT ERP integration, businesses can improve both data quality and quantity with the help of smart sensor connectivity and secure data encryption that sends the information to the ERP system without affecting the quality. The data encrypted with IoT sensors will reach straight to the ERP software. If any information goes through modifications, it will be updated in the software without any errors.

2. Improved product quality in Cold Chain:

There is a specific category of items that are required to be maintained under certain conditions and temperature thresholds such as food products, medicines, or organs for an organ transplant. If you deviate from temperature specifications at the warehouse or in transit, it could make your product unusable and a total waste. The real-time sensor of IoT solutions safeguards those shipments against such risks and preserves their quality.

3. Greater Supply Chain Management:

The movement of inventory gets monitored during their whole journey, so businesses are kept informed from time to time regarding their location. With the help of smart sensors, IoT solutions can feed information about the precise condition of inventory. It allows supply chain managers to connect vehicles, equipment, and devices for a real-time status update on jobs. This can deliver an end-to-end supply chain picture i.e., from manufacturers to customers via the warehouse. Therefore, instead of giving job status as “in transit”, managers are informed about the precise location of the vehicle. This helps the managers to make timely decisions so that there lies no obstruction in the movement of goods.

4. Disaster Planning and Recovery:

IoT ERP integration for disaster management and recovery can prove to be the biggest game-changing future trend. With IoT sensors and critical warning systems, real-time data can help in effective monitoring and analysis. For instance, IoT sensors can effectively detect the rise in harmful gases in certain industry units and can automatically shut down the system with a raised alarm.

5. Real-time Management of Critical Data:

With the help of interconnected IoT assets, enterprises can capture vast troves of real-time data that helps in tracking assets, products, and day-to-day operations. These insights can, furthermore, assist in remote asset monitoring, fraud detection and security, and real-time supply chain visibility.

6. Upgraded Shop Floor Performance:

We know that ERP automates manual processes, but IoT goes even further. IoT minimizes manual labor and enhances productivity by allowing ERP to achieve real-time production visualization and simplifies operations to provide step-by-step procedures. This increased automation with IoT will help streamline activities, reduce waste and improve profitability.

7. Enriched Forecasting:

IoT ERP integration helps companies successfully plan for the future. Greater information is available about customers’ behavior of finding, buying, and using products and services. IoT data helps businesses identify patterns and precedents to make informed decisions around production. This added information will help companies to forecast and plan with utmost accuracy.

8. Ensuring Environmental Sustainability:

The integration of ERP with IoT helps businesses be environment-friendly by automating business processes so that they are more efficient to reduce wastages and emissions. IoT smart sensors can detect gas leakages to prevent pollution and hazards in the company’s premises. It collects data, enabling optimum utilization of resources and constantly reusing materials and components. It also optimizes truck routes to reduce the amount of fossil fuel consumed and it also helps machines operate in the most efficient ways to minimize carbon footprints.

Challenges of IoT ERP Integration:

Along with several benefits, IoT integration with ERP also holds some challenges which make companies reluctant and unenthusiastic to include IoT technology in their enterprise applications. The obstacles to overcome are as follows:

1.Maintaining the Legacy:

Often companies are unwilling to adapt to new technologies as they get comfortable working with legacy equipment. If you are working with older established solutions, it can become more challenging and all the more reason to not implement IoT. Legacy systems are well-suited to manage structured data and unfortunately, most IoT/business interactions generate unstructured and ambiguous data.

2. Cyberattacks and Brute Force Attacks:

As per the survey conducted by Business Wire, almost half of the US firms using IoT devices have faced security breaches. As IoT infrastructure is an amalgamation of sensors, gateways, hardware, and application software, it makes the intact system vulnerable to security breaches and the probability of gaining access to vast amounts of data through cyberattacks and brute force attacks is astronomical.

3. State of "Gold Rush":

There are again many reasons behind the state of fear and insecurity in IoT. Some of it is related to the “gold rush” state of industries where every vendor is just hastily seeking to connect and implement the next innovative gadget or technology respectively before the competitors do. In those circumstances, functionality becomes the priority and security takes a back seat. There are reports indicating that countless IoT devices that power everyday technology like closed-circuit cameras, thermostats, drug infusion pumps, and smart home devices like monitors, and smart fridges were hijacked by the malware and used against the servers.

4. Connectivity:

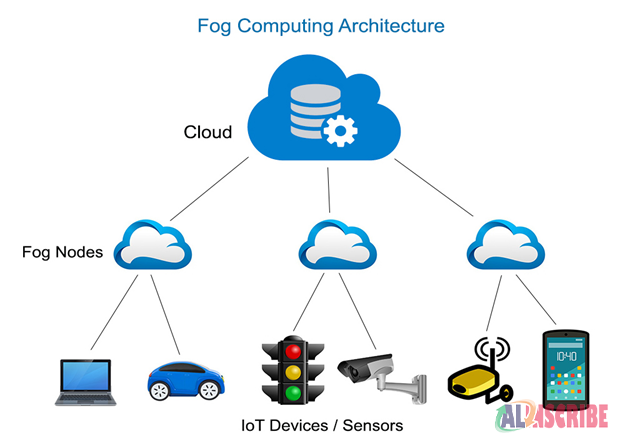

One of the biggest challenges of the future of IoT is connectivity which will defy the present structure of current communication models and the underlying technologies. In the current scenario, we rely on the centralized server/client paradigm to authorize, authenticate and link different nodes in a network which is sufficient for existing IoT ecosystems where hundreds and thousands of devices are involved. But what happens when the network starts to grow to join billions of devices and maybe more than that? The centralized brokered systems will turn into a bottleneck. Entire system can be doomed if the server becomes unavailable and a bottleneck situation occurs. Therefore, the future of IoT very much has to depend on decentralizing IoT networks.

Solutions like Fog Computing models where smart devices such as IoT hubs take charge of time-critical operations and Cloud servers take responsibility for data gathering and analytical responsibilities.

5. Transparency Issues:

There are companies (data brokers) that sell data gathered from various sources. Data is the currency of IoT and still, regulatory standards are missing for the data markets. There is a lack of transparency about who gets access to what data and how those crucial data is used to manufacture products and sold to advertisers and third parties. Thus, there is an implied need for clear guidelines on the retention, use and disclosure, and security of data including metadata.

Tips to Ensure a Successful IoT ERP Integration:

We already have discussed the benefits that an integrated IoT-ERP solution brings, as well as the challenges surrounding the integration. Now, considering you already have an ERP system in place, what steps you can take to gain advantage of an IoT product? Let us take a look at the steps you need to accomplish from a “business stand-point”, to set up a positive ERP-IoT integrated solution:

- Realizing that being “digital” does not mean you need to replace your ERP system. Rather critical business objectives must be identified where an IoT solution can add value to and intensifies your business. The business objective could be to scrutinize thoroughly the temperature of shipments, implement theft protection for extravagant and overpriced medicines, or keep track of assets like in a construction company where you have to deal with expensive equipment.

- Test before you buy. You must run a “proof-of-concept (POC)” with several test IoT devices before adopting one.

- Define your criteria for “success” and timeline for your POC

- Specify which mode of transport is key to your business (truck, railways, air, ocean, or multi-modal)

- Determine if this test will be conducted “locally” or “globally”

- Check whether the introduction of IoT devices creates any teething issues with your shipping and logistics teams during the POC. How will it work in your warehouse and how to attach the device to your shipping containers?

- Make sure you get management buy-in on the basis of the results of the POC. Ask yourself if there are any new services you can provide to your end consumer to add value or increase revenues. For instance, high-end automobiles can be traced from the manufacturing site to the customers- which is a value-added service.

- Inspection of Regulatory Compliances. When you think that you are just good to go, the last thing you must conform to is the regulatory requirements of your industry. Make sure they are placed. For example, FDA compliance may necessitate that every material lot needs to be temperature tracked and summary data documented in the form of an audit report.

Closing Comment: Is the integration really worth it?

In next few years, connected devices will be found everywhere -in smart factories, smart cars, smart retail stores, smart hospitals, smart cities and buildings and many other applications that are yet to be discovered. Each industry will find new ways and techniques to use the intelligence imparted by IoT, such as improving manufacturing processes, customer experiences, and energy efficiency, just to state a few examples. The ability to analyze data from every link of the manufacturing value chain helps companies establish better control over manufacturing processes to keep production up and running and reduce costs.

Article Comments

Similar Articles

Articles Search

Sponsor

There are zero sub-categories in this parent category.

There are zero sub-categories in this parent category.

There are zero sub-categories in this parent category.